Developing a safe and effective device for SCI, the smart way

By ONWARD

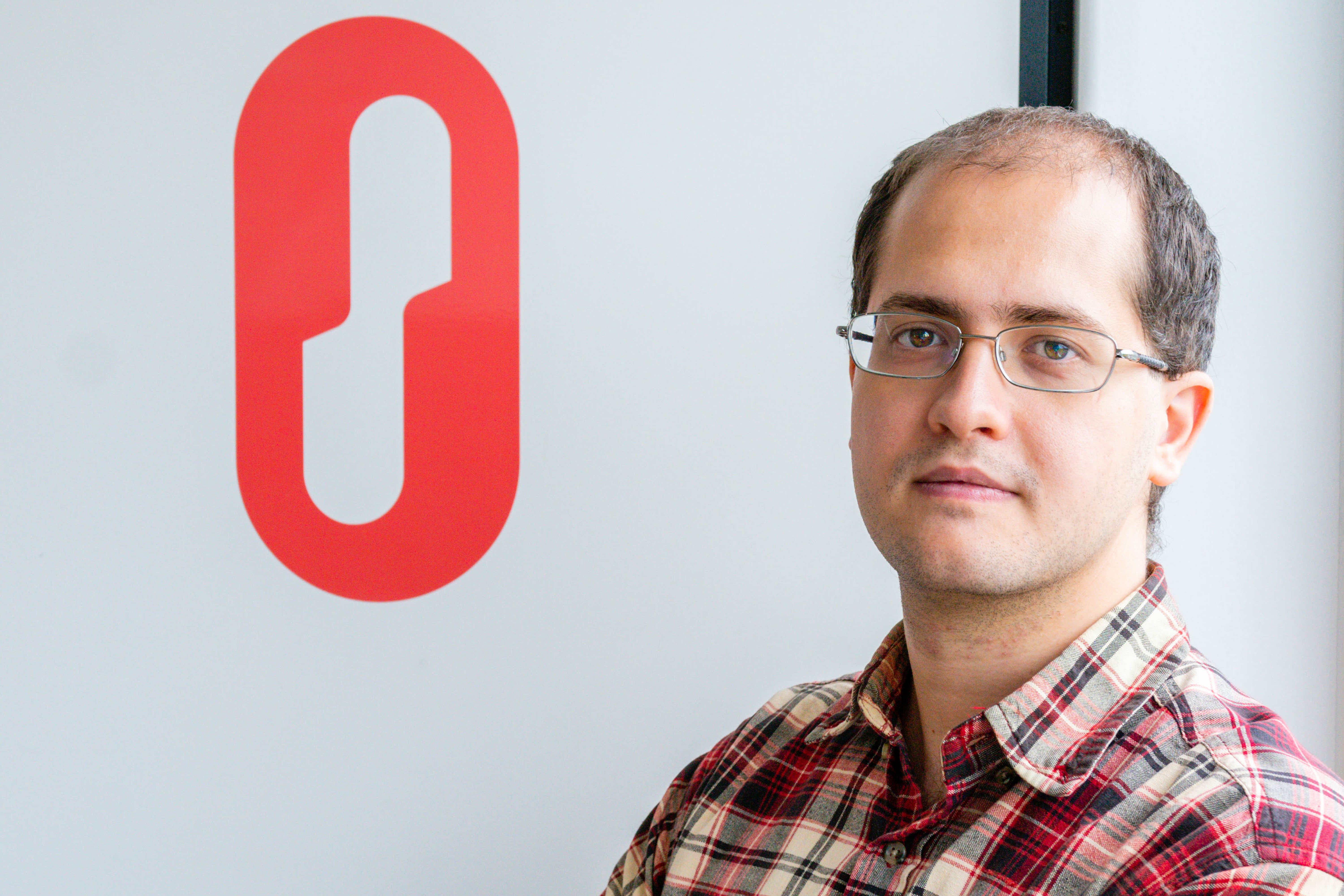

Edo is on a mission: Ensure the ONWARD engineering team produces a device that is safe and effective for people with spinal cord injury. The formula sounds simple: get the design process right from the start, ensure all teams are working in sync, and automate the most tedious testing tasks. In other words, do it the smart way! The reality is far more complex. But that’s just the kind of challenge Edo relishes. With degrees in electronics and medical device design, he has spent the past two years developing virtual models and testing protocols for the ARC-IM as part of his Professional Doctorate in Healthcare Systems Design at Eindhoven University, all while working for ONWARD.

"When I tell people what I do, the reaction is often, 'Wow, you’re doing something important!' That makes me even more excited and proud to be doing what I do."

You are part of the team responsible for developing the ARC-IM platform. Can you describe what you do?

My title is system and clinical engineer, but my focus is mainly on the system. My team serves as the link between the software, electronics and quality teams. We define the architecture of the ARC-IM system and its requirements. Next, once we have a working prototype, a big part of my job is what we call integration: bringing all the parts together and verifying that they actually work. Because it’s such a complex system, we split the work into different sub-modules and teams. But then, the risk is that when we put everything together, it might not function as we want. That’s why it’s so important to make sure that, from the start of the design process, all the teams are communicating effectively with each other. I make sure that happens.

What project are you focusing on right now?

We’re currently in the “design, verification, and testing” phase. We create tests to verify that the system meets each of our design requirements. We then check whether it passes or fails. It's a very important phase to build confidence in the system. You might think that we’d be disappointed to find that something isn’t working properly. But in fact, we want to find as many bugs as possible now, so we can fix them before we release the product to market. We really don’t want users to be finding the bugs!

Hunting bugs sounds tedious and time-consuming! Have you found ways to speed it up?

Our CTO John Murphy has pushed hard for automated testing. Ideally he would like to see tests running on the system 24/7. We know that by stressing the system we will be able to identify problems that wouldn’t come up otherwise. And because we’re engineers, we want to do it the smart way, rather than sit for hours in front of a computer! So, we're spending a lot of time automating as many tests as possible, so we can run them overnight and let the computers do the work for us, and check in the morning where the system passed or failed.

When did you become interested in medical devices?

I’ve always found the human body fascinating. After high school, I hesitated between medicine and engineering. Did I really want to spend the next years memorizing all the bones in the body? When I discovered the biomedical field, I thought, “Great, I can be an engineer but still do something related to medicine”. I didn't want to design a new phone: I wasn't interested in that. I wanted to work on something that had an impact and would change people's lives. I studied electronics for my BSc. in Rome and then moved to Germany for my Master’s in biomedical engineering. At the time, I was fascinated by artificial organs. I was drawing an artificial heart in my head! Then I started learning about devices like pacemakers and neural stimulation, where my background in electronics was a better fit. After graduating, I joined Medtronic in Eindhoven to work on deep brain stimulation to relieve the symptoms of Parkinson's disease, which include paralysis. When my boss at the time moved to ONWARD to work on implantable technology for SCI, he suggested I join him there.

You work in Eindhoven, which is a major technology and design hub in the Netherlands. How would you describe the culture at ONWARD?

It’s a very dynamic environment, generally. The company has grown a lot in the four years since I joined, and there’s been a fair amount of movement. It’s just a great team: I feel like I have only friends here. At the end of the day, if there’s a good vibe and everybody helps and respects each other, that's what makes a good company culture. I think the spirit of being part of something bigger than yourself really has an impact – we’re changing the lives of people with SCI. When I tell people what I do, the reaction is often, “Wow, you’re doing something important!" That makes me even more excited and proud to be doing what I do.

What two words best describe ONWARD for you?

I’ve mentioned teamwork and respect already. I think trust is also very important. The attitude here is, “I trust you to do your job, I don't need to constantly supervise and micromanage you.” Everybody feels their work is important. For me, that’s essential. Even interns are given a lot of independence and responsibility, and an opportunity to contribute.

You graduated last year with a PDEng in Healthcare Systems Design from Eindhoven University of Technology. How did you combine postgraduate study and working at ONWARD?

The Professional Doctorate in Engineering is an industry-oriented degree that lasts two years instead of four for a standard PhD. It was perfect for me, as it gave me the opportunity to go back to university while keeping my job. And ONWARD was very supportive: they understood that they had something to gain from it, too. My PDEng project was to design a computer model for the “lead”, the part of ARC-IM system that’s implanted next to the spinal cord, to determine how it performed on virtual patients. At the startup stage, you can dream big, but the budget is small. So, you have to come up with a minimum viable product that you think is the best fit, which is what we did with the help of my model. We’re now modelling the next generation of leads, which will have different shapes depending on where on the spinal cord they will be implanted to support our many therapies in development.